Electrodes that protect themselves

Scientists at three Department of Energy national laboratories claim to have discovered how to keep a lithium ion battery cathode from developing a coating that degrades its performance. The teams used a manufacturing technique to form the cathode material into tiny, layered particles that store a lot of energy while protecting themselves from damage.

Scientists at three Department of Energy national laboratories claim to have discovered how to keep a lithium ion battery cathode from developing a coating that degrades its performance. The teams used a manufacturing technique to form the cathode material into tiny, layered particles that store a lot of energy while protecting themselves from damage.

The scientists reported that the test batteries that included this cathode material held up better when charged and discharged at the voltages needed to fast-charge electric vehicles.

"We were able to engineer the surface in a way that prevents rapid fading of the battery's capacity," said Yijin Liu, a staff scientist at SLAC National Accelerator Laboratory. The results potentially pave the way for making lithium-ion batteries that are cheaper and have higher energy density.

Cathodes made of nickel manganese cobalt oxide (NMC) are an especially hot area of battery research because they can operate at the voltages needed to store a lot of energy in a very small space.

But, Huolin Xin of Brookhaven National Laboratory said, while the nickel in NMC gives it a high capacity for storing energy, it's also reactive and unstable, with a tendency to undergo destructive side reactions with the electrolyte. Over time this forms a rock salt-like crust that blocks the flow of lithium ions.

In this study, the researchers experimented with ways to incorporate nickel but protect it from the electrolyte.

A team led by Marca Doeff at Lawrence Berkeley National Laboratory sprayed a solution of lithium, nickel, manganese and cobalt through an atomiser nozzle to form droplets that decomposed to form a powder. Repeatedly heating and cooling the powder triggered the formation of tiny particles that assembled themselves into larger, spherical and sometimes hollow structures.

This technique, called spray pyrolysis, is said to be cheap and could be scaled up for commercial production. During this process the NMC particles emerged with their basic ingredients redistributed.

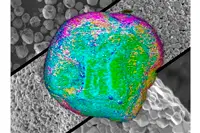

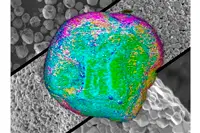

The cathode particles were examined at SLAC and Brookhaven. At SLAC's Stanford Synchrotron Radiation Lightsource, Liu and his colleagues used X-rays to probe the particles at a scale of 10 to 20µm. At Brookhaven's Centre for Functional Nanomaterials, Xin and his team used a scanning transmission electron microscope to zoom in on nanoscale details.

With both techniques and at every scale they looked, the particles had a different structure than the original starting material. Only 70% of them contained all three of the starting metals - nickel, manganese and cobalt.

"The particles have more nickel on the inside, to store more energy, and less on the surface, where it would cause problems," Liu said. At the same time, the surface of the particles was enriched in manganese, which acted like a coat of paint to protect the interior.

In future experiments, the researchers plan to probe the NMC cathode with X-rays while it's charging and discharging to see how its structure and chemistry change. They also hope to improve the material's safety.

"To make a real, functional battery that can be commercialised, you have to look beyond performance," Liu said. "Safety and many other things have to be considered."

Author

Tom Austin-Morgan

Source: www.newelectronics.co.uk

Scientists at three Department of Energy national laboratories claim to have discovered how to keep a lithium ion battery cathode from developing a coating that degrades its performance. The teams used a manufacturing technique to form the cathode material into tiny, layered particles that store a lot of energy while protecting themselves from damage.

Scientists at three Department of Energy national laboratories claim to have discovered how to keep a lithium ion battery cathode from developing a coating that degrades its performance. The teams used a manufacturing technique to form the cathode material into tiny, layered particles that store a lot of energy while protecting themselves from damage.