The desire to gather more information about manufacturing equipment embodied in Industry 4.0 is pushing sensor manufacturers to make smaller, but more capable devices which generate less heat.

The desire to gather more information about manufacturing equipment embodied in Industry 4.0 is pushing sensor manufacturers to make smaller, but more capable devices which generate less heat. The desire to gather more information about manufacturing equipment embodied in Industry 4.0 is pushing sensor manufacturers to make smaller, but more capable devices which generate less heat.

The desire to gather more information about manufacturing equipment embodied in Industry 4.0 is pushing sensor manufacturers to make smaller, but more capable devices which generate less heat.

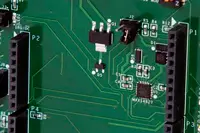

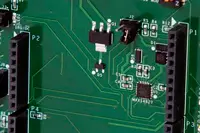

Looking to help them meet these challenges, Maxim Integrated has launched the MAX14827, a dual channel 250mA IO-Link transceiver which is said to integrate the high voltage functions commonly found in industrial sensors, including two low power drivers with active reverse polarity protection to reduce downtime. It also includes 3.3V and 5V linear regulators for low noise analogue/logic supply rails.

The third generation device, specified at Maxim’s Munich facility, is intended to provide manufacturers with flexibility. Reinhardt Wagner, senior corporate applications engineer, said: “There are many types of sensor and different levels of complexity. For example, it could be an intelligent device or a simple binary switch. Our intent was to develop a flexible chip to meet these needs.”

Sensors that work in association with an MCU can use the SPI interface, while IO-Link operation is supported by a three wire UART interface. A multiplexed UART/SPI option allows a serial MCU interface to be shared by the SPI and UART interfaces.

A typical on-resistance of 2.5? is said to cut power dissipation by half, while the 2.5 x 2.5mm chip scale package saves space. Specified for temperatures ranging from -40 to 125°C, the part is also available in a 4 x 4mm TQFN.

Author

Graham Pitcher

Source: www.newelectronics.co.uk