Siemens has announced the introduction of PAVE360 Automotive, a new category of digital twin software engineered to support development of software-defined vehicles (SDVs). The cloud-based solution aims to significantly shorten the time and effort automakers and suppliers need to build and test full vehicle systems virtually before physical prototypes are available.

Conceptual view of a software-defined vehicle.

Traditional automotive workflows often require actual hardware before meaningful software integration can begin. PAVE360 Automotive challenges this by offering a ready-to-use system-level digital twin that mirrors complete vehicle hardware and software. This enables teams to start co-design, integration, testing and validation from the outset.

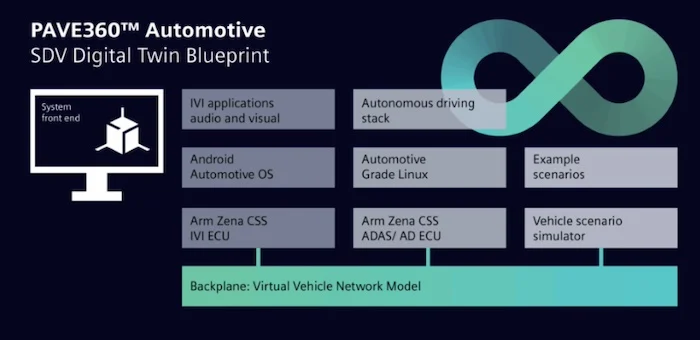

Unlike component-level simulation tools, the PAVE360 platform provides a comprehensive digital twin blueprint that combines models of advanced driver-assistance systems (ADAS), autonomous driving (AD) software, in-vehicle infotainment (IVI) and vehicle networks into a unified environment.

PAVE360 Automotive is designed to bridge gaps between cross-discipline groups. Hardware designers, software engineers and systems integrators can work concurrently in a shared digital environment, improving early visibility into system interactions and reducing the risk of late-stage integration issues.

The platform also supports integration with third-party tools and real hardware, letting teams validate virtual models against physical test setups when needed.

Overview of the PAVE360 Automotive SDV digital twin blueprint.

Overview of the PAVE360 Automotive SDV digital twin blueprint.

Siemens is currently offering PAVE360 Automotive to select customers, with broader availability expected soon. The company showcased the platform publicly at CES 2026. As automakers increasingly adopt software-first approaches, tools like PAVE360 aim to streamline workflows, encourage earlier verification and help manage the complexity of modern vehicle development.