Electronics News

Archive : 24 April 2017 год

Ice templating could lead to lithium batteries that are safer, have longer battery life and are bendable, according to research undertaken at Columbia University’s Engineering department.

Ice templating could lead to lithium batteries that are safer, have longer battery life and are bendable, according to research undertaken at Columbia University’s Engineering department.

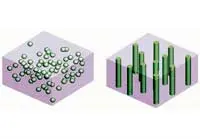

Looking to overcome issues associated with the liquid electrolyte used in commercial lithium batteries, assistant professor Yuan Yang’s team explored using a solid electrolyte. In particular, the team was interested in using ice-templating to create vertically aligned structures of ceramic solid electrolytes. These, said the team, would provide fast lithium ion pathways and be highly conductive.

To create these, an aqueous solution with ceramic particles was cooled from the bottom and ice allowed to grow. A vacuum was then applied to transition the solid ice to a gas, leaving a vertically aligned structure. This ceramic structure was then combined with a polymer to provide mechanical support and flexibility.

“Flexible solid state lithium batteries not only solve the safety issues but may also increase battery energy density for transportation and storage. And they show great promise in creating bendable devices,” said Yang.

The team says its approach could, in principle, improve the energy density of batteries. By using the solid electrolyte, the lithium battery’s graphite anode could be replaced by lithium metal, boosting specific energy by up to 70%.

Researcher Haowei Zhai added: “We believe this is the first time anyone has used the ice-templating method to make a flexible solid electrolyte in lithium batteries. This opens a new approach to optimize ion conduction for next-generation rechargeable batteries.”

Author

Graham Pitcher

Source: www.newelectronics.co.uk

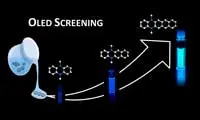

Using a screening process developed by chemists at Goethe University Frankfurt, it is now possible to identify more quickly structures for organic light-emitting diodes (OLEDs) with superior luminescence and charge-transport properties.

Using a screening process developed by chemists at Goethe University Frankfurt, it is now possible to identify more quickly structures for organic light-emitting diodes (OLEDs) with superior luminescence and charge-transport properties.

According to the researchers, organic materials are the most effective way to master the rising demand for display technology. In particular, molecules from the class of materials known as polycyclic aromatic hydrocarbons (PAHs) can be used to produce large and flexible flat screens with high resolution and low energy consumption.

The research team is working on new types of organic luminescent materials which owe their promising properties to the introduction of boron atoms into the PAH scaffold but the syntheses required have been complex and time-consuming.

A recently developed screening process, which makes a variety of boron-doped PAHs quickly and easily accessible, could in future alleviate this situation. The technique makes it possible to evaluate their potential as OLED materials.

“For a long time, it has been pharmaceutical research which has profited from screening processes,” says doctoral researcher Alexandra John. “Yet it makes sense in the dynamic and growing field of organic materials to use similar strategies to achieve results in a cost-efficient and resource-friendly way.”

The method is said to be based on a three-component reaction: Two components remain unchanged in all reactions whilst the third is chosen from a range of cheaply available PAHs. The reactive boron-containing starting material plays an important role in the assembly of the molecular scaffold.

In addition, it is said to give the compounds obtained the desired optoelectronic properties by increasing luminescence and improving the materials’ electrical conductivity.

Author

Peggy Lee

Source: www.newelectronics.co.uk

Thin carbon nanotube (CNT) textiles, synthesised by researchers at the University of Illinois at Urbana-Champaign, exhibit both high electrical conductivity and a level of toughness that is about 50 times higher than copper films currently used in electronics.

Thin carbon nanotube (CNT) textiles, synthesised by researchers at the University of Illinois at Urbana-Champaign, exhibit both high electrical conductivity and a level of toughness that is about 50 times higher than copper films currently used in electronics.

“The structural robustness of thin metal films has significant importance for the reliable operation of smart skin and flexible electronics including biological and structural health monitoring sensors,” explained assistant professor Sameh Tawfick.

“Aligned carbon nanotube sheets are suitable for a range of applications, spanning the micro- to the macro-scales including MEMS, supercapacitor electrodes, electrical cables, artificial muscles, and multi-functional composites.

“To our knowledge, this is the first study to apply the principles of fracture mechanics to design and to study the toughness of nano-architectured CNT textiles. The theoretical framework of fracture mechanics is shown to be very robust for a variety of linear and non-linear materials.”

According to the research team, it has proven difficult to construct fabrics or films from carbon nanotubes that demonstrate the required properties on centimetre or metre scales. The challenge stems from the difficulty of assembling and weaving CNTs since they are so small, and their geometry hard to control.

“The study of the fracture energy of CNT textiles led us to design these extremely tough films,” stated former graduate student Yue Liang.

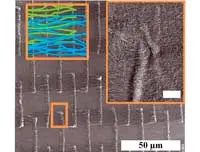

Beginning with a catalyst deposited on a silicon oxide substrate, vertically aligned CNTs were synthesised via chemical vapour deposition in the form of parallel lines of 5µm width, 10μm length, and 20 to 60μm heights.

“The staggered catalyst pattern is inspired by the brick and mortar design motif commonly seen in tough natural materials such as bone, nacre and bamboo,” Liang added. “Looking for ways to staple the CNTs together, we tried several mechanical approaches to simultaneously re-orient the nanotubes, before finally using the self-driven capillary forces.”

Pic: Colored schematic shows the architecture of self-weaved CNTs, and the inset shows a high resolution SEM of the inter-diffusion of CNT among the different patches due to capillary splicing.

Author

Peggy Lee

Source: www.newelectronics.co.uk

Nanosilicon anodes for high performance lithium-ion batteries have been created by researchers at the University of California, Riverside's Bourns College of Engineering, using waste glass bottles and a low cost chemical process.

According to the researchers, the batteries could extend the range of electric vehicles and plug-in hybrid electric vehicles, and provide more power with fewer charges to personal electronics like cell phones and laptops.

"We started with a waste product that was headed for the landfill and created batteries that stored more energy, charged faster, and were more stable than commercial coin cell batteries. Hence, we have very promising candidates for next-generation lithium-ion batteries," graduate student Changling Li said.

Silicon anodes are said to store up to 10 times more energy than conventional graphite anodes, but expansion and shrinkage during charge and discharge make them unstable.

Downsizing silicon to the nanoscale has been shown to reduce this problem, and by combining a relatively pure form of silicon dioxide and a low cost chemical reaction, the researchers created lithium-ion half-cell batteries that store almost four times more energy than conventional graphite anodes.

To create the anodes, the team used a three-step process that involved crushing and grinding the glass bottles into a fine white power, a magnesiothermic reduction to transform the silicon dioxide into nanostructured silicon, and coating the silicon nanoparticles with carbon to improve their stability and energy storage properties.

One glass bottle is said to provide enough nanosilicon for hundreds of coin cell batteries or three-five pouch cell batteries.

Author

Peggy Lee

Source: www.newelectronics.co.uk